The White Crystals of Life: Exploring the Salt-Making Process from the Ocean to Our Tables

By. Tri - 19 May 2025

lautnusantara.com_ Salt, an essential seasoning that not only flavors our food but also plays a vital role in maintaining our body's electrolyte balance. Behind its simple white grains lies a fascinating process that has been carried out for centuries. Let's delve deeper into how salt, especially sea salt, is produced from the vastness of the ocean to become an indispensable part of our daily meals.

In many coastal regions, including Indonesia with its long coastlines, traditional salt production is still a common sight. This method relies on the wonders of sunlight and the abundance of seawater. The process begins with careful land preparation. Salt farmers select flat land near the coast and construct shallow ponds with sturdy embankments. The soil within these ponds is compacted to prevent water seepage.

The next step is seawater intake. Seawater, rich in minerals and salt, is pumped or channeled into a series of ponds. This process usually starts in larger ponds, which serve as initial evaporation ponds. Under the heat of the sun, the seawater gradually evaporates, leaving behind an increasingly concentrated salt solution.

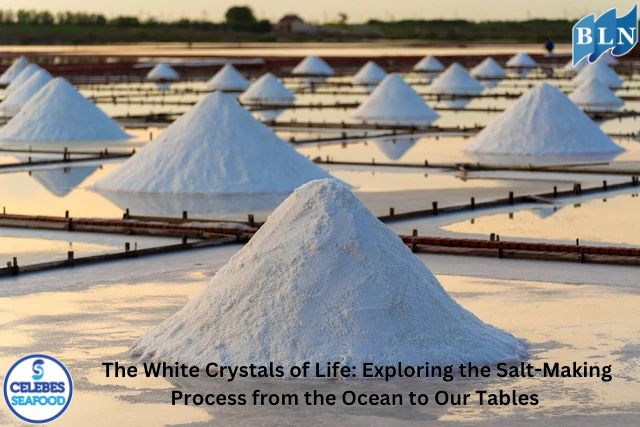

As the water volume decreases, this more concentrated brine is then transferred to smaller and shallower ponds called crystallization ponds. This is where the real magic happens. The sun's heat continues to work, evaporating the remaining water until the salt reaches its saturation point. At this point, salt crystals begin to form at the bottom of the ponds, appearing like shimmering white blankets.

This crystallization process requires patience and skill. Salt farmers must have a thorough understanding of weather conditions and the water's salinity level to produce high-quality salt crystals. The time needed for crystallization can vary depending on the intensity of sunlight, air temperature, and the surface area of the ponds.

Once the salt crystals have reached the desired size, it's time for harvesting. Using simple tools such as wooden rakes or shovels, salt farmers collect the salt crystals from the bottom of the ponds. This harvested salt is then piled into small heaps along the edges of the ponds for further drying under the sun. The aim is to reduce any remaining moisture and ensure the salt becomes more durable.

In some cases, the harvested salt may undergo a process of washing and cleaning using cleaner seawater to remove any dirt, mud, or other particles that may have been carried in during the evaporation and crystallization processes. Once clean and dry, the salt is ready for packaging and distribution to various markets, ready to add flavor to the meals on our tables.

In addition to the traditional method that relies on the power of nature, modern industry has also developed more efficient ways of producing salt that yield a more consistent product quality. Industrial methods often use technologies like vacuum evaporators to accelerate the seawater evaporation process in a closed environment. Nevertheless, the traditional method retains its own appeal, not only for its simplicity but also for its connection to local wisdom and the direct utilization of natural resources.

From the vast expanse of the ocean to becoming a seasoning in our kitchens, salt undergoes a long journey involving the interaction between nature and human ingenuity. The salt-making process, whether traditional or modern, is a testament to how natural resources can be transformed into an essential element of our lives. Understanding this process deepens our appreciation for every white grain that flavors our daily meals.

If you are interested in our Coral Trout Fillet Skin On, CORAL TROUT WGG WHOLE GILLED GUTTED, TOMATO COD WHOLE GILLED GUTTED please do not hesitate to contact us through email and/or whatsapp.