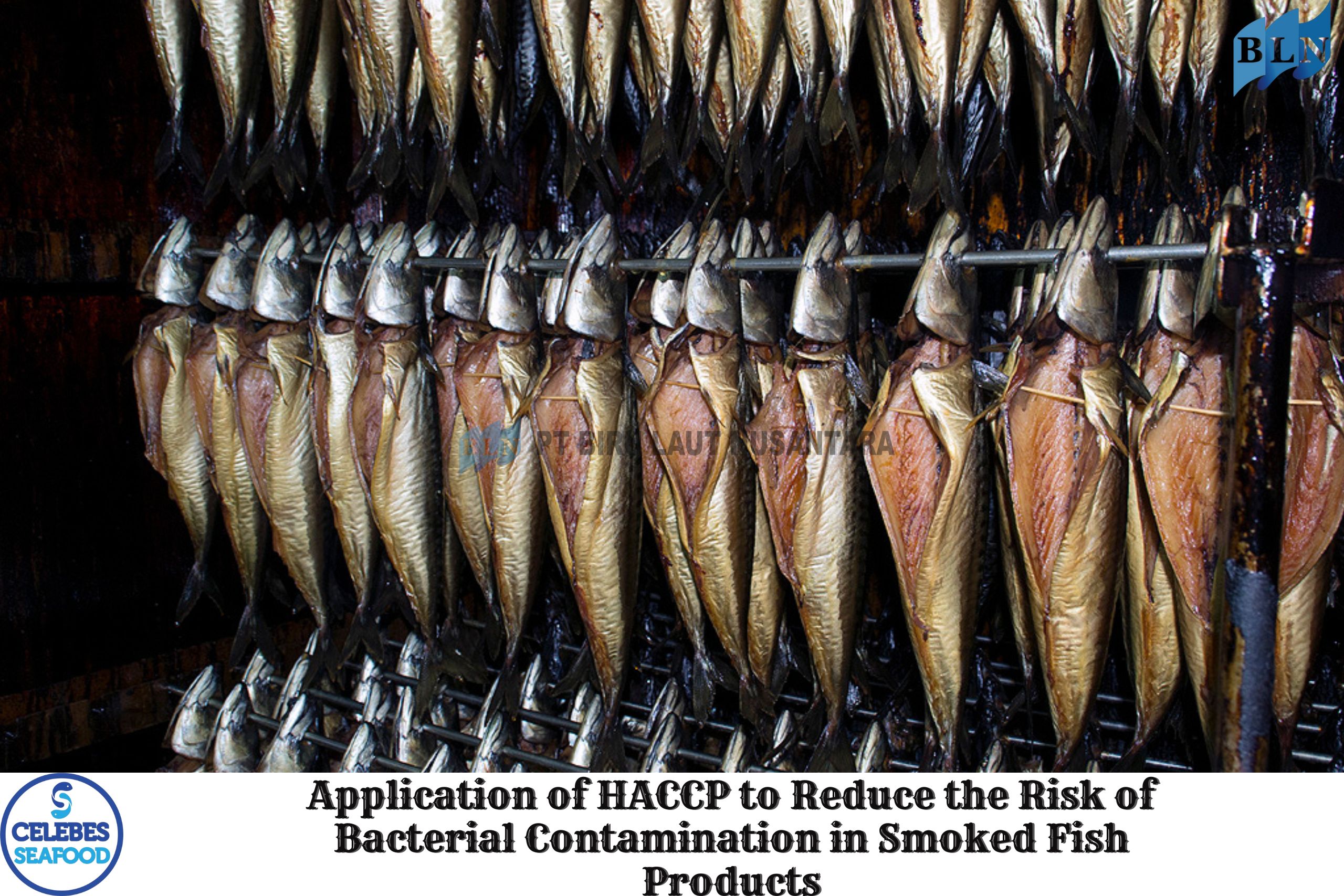

Application of HACCP to Reduce the Risk of Bacterial Contamination in Smoked Fish Products

By. Azizah - 30 May 2025

lautnusantara.comSmoked fish products are popular processed fishery commodities but are vulnerable to bacterial contamination if not handled properly. This article discusses the implementation of the Hazard Analysis and Critical Control Points (HACCP) system as a preventive approach to reduce the risk of bacterial contamination in smoked fish products. Through the identification of critical control points and the application of appropriate controls, the HACCP system can enhance the safety and quality of smoked fish products in the market.

Introduction

Smoking is one of the traditional preservation methods still widely used in fish processing. Although this method can extend the shelf life of fish, bacterial contamination such as Listeria monocytogenes, Salmonella, and Clostridium botulinum remains a serious threat to food safety. Therefore, a systematic approach such as HACCP is essential to ensure product safety before it reaches consumers.

Benefits of HACCP Implementation in Smoked Fish:

-

Food Safety:

Ensures smoked fish products are safe for consumption by reducing the risk of bacterial contamination and foodborne illnesses. -

Product Quality:

Improves the quality of smoked fish products as the production process is properly controlled. -

Consumer Trust:

Enhances consumer confidence in the safety and reliability of smoked fish products -

Increased Competitiveness:

Helps producers meet food safety standards, thereby increasing the competitiveness of their products in the market.

HACCP Implementation Methods in Smoked Fish

HACCP implementation consists of seven core principles, starting from hazard analysis to record-keeping and documentation. In the processing of smoked fish, the critical control points include:

-

Raw material reception – inspection of fresh fish quality.

-

Salting process – control of brine concentration and soaking time.

-

Smoking process – control of temperature and smoking duration.

-

Cooling and storage – prevention of microbial growth after processing.

Each critical control point must be identified, monitored, and controlled in accordance with food safety standards.

Results and Discussion

The implementation of HACCP has proven effective in reducing bacterial contamination levels in several smoked fish processing units in Indonesia. Evaluations showed a significant decrease in microbial counts after applying HACCP, especially during the smoking and storage stages. Additionally, workforce training and proper documentation of procedures have contributed to better compliance with hygiene and food safety standards.

If you are interested in our Coral Trout Fillet Skin On, CORAL TROUT WGG WHOLE GILLED GUTTED, TOMATO COD WHOLE GILLED GUTTED please do not hesitate to contact us through email and/or whatsapp.

in Ball Shape (Balltype) for Export.jpg)

.jpg)